Geoelectrical Real-time Ground Prediction While

TBM-Boring

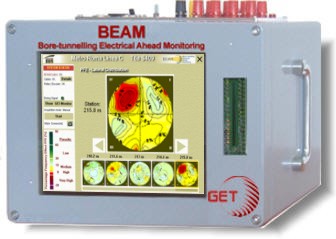

The Bore-Tunnelling Electrical Ahead Monitoring - BEAM® -, developed and patented by Kaus et. al., managing director of GET, is a geophysical ground prediction technique especially designed for the underground construction industry.

Supplied on a rental basis, it is increasingly ordered since the year 2000 to serve at more than 80 international TBM projects, thereof 74 TBM projects with a total length of more than 300 km

Beside the standard TBM operations, special applications has been performed for drill & blast drives and also perimeter investigations for cavity detection in karst formation around existing tunnels.

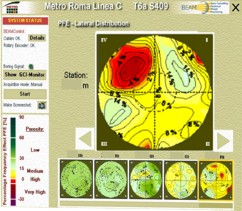

BEAM SCAN mode at Highway tunnel Galleria

SPARVO in

Italy, 2011-2012: EPB Ø 15.55m

Real-time Ahead Monitoring for TBM Drives

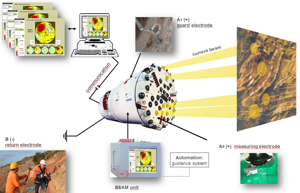

BEAM is a non-intrusive focused-electrical induced polarisation ground prediction technique, permanently operating while TBM tunneling.

It is a robust and reliable long-term operating geophysical probing technique fulfilling the practical demands under the rough conditions of tunnelling work in hard rock as well as in soft ground.

Main components of the survey system are the measuring instrument placed in the TBM operator cabin and special adapted excavation tools which are used as electrodes. The unit is connected to the guidance system and receives the boring signal which allows fully automatic data acquisition and visualisation in real-time on an integrated monitor. Communication facilities transfer the forecast results to every accredited computer world wide simultaneously.

Based on the measuring data the percentage frequency effect PFE and the resistivity R, an advanced evaluation software is established for geoelectrical-geological/ hydrogeological classification and interpretation.

Early warning information of significant ground changes while tunnelling is advantageous to reduce hazardous risks, in particular during excavation with tunnel boring machines. Accidents or complications and hence expensive standstills can be prevented by planning precautionary and logistical measures.

On the condition that TBM operations and lining works should not be obstructed by data acquisition, a probing and documentation without predrillings is one major demand. On the other hand knowledge of non-critical ground conditions ahead of the face allows rapid excavation resulting in high production rates and contributes to shield staff and equipment.

BEAM Multi Channel Unit

Early warning information for critical ground while TBM boring reduces hazardous geo risks like enhanced water-inflow

System

Method

Visualisation

Our Global Network

HYDROSCAN (HSC), ORESCAN (OSC),

Electrokinetic Pore-fluid Mixer (EPM)

About us

![]() GEO EXPLORATION TECHNOLOGIES - GET - is a German geophysical service company experienced in exploration of subsurface ressources, structures and properties serving numerous national and international projects since 1986.

GEO EXPLORATION TECHNOLOGIES - GET - is a German geophysical service company experienced in exploration of subsurface ressources, structures and properties serving numerous national and international projects since 1986.

News & Events

BEAM - Real-time Ahead Monitoring System

BEAM system is currently installed at

following TBM Projects:

BOVINO ORSARA PROJECT -

LINEA FERROVIARIA NAPOLI-BARI in Italy

MESSINA-CATANIA RAILWAY LINE in Italy

DELHI METRO - DMRC DC05 in India

OMOIGAWA WATER TUNNEL in Japan

South Africa - HSC, OSC, EPM - Sea Fox Int.

South Africa - HSC, OSC, EPM - Sea Fox Int.